I never disconnected the original factory horn when I installed the oogah horn--I always added another horn circuit. To me it wasn't a replacement to a factory horn, but an addition. It was my party horn. It was the horn I used when I was among friends or family. It was the horn of choice when I wanted to scare somebody walking in front of my truck. I missed it.

A few years ago I started looking a few years ago for a replacement, and it had to be a genuine Hutchins brand. There are still some out there, but it's hard to find one (12-volt especially) that works for under $100, and if you do it's going to be ugly. I finally found one on eBay and plunked down $45 for it, and yes--it was ugly. It didn't work but was basically intact. I knew I could get it working. I didn't save a good picture from the eBay ad, but I do have this small, ugly one. You can see it was in tough shape when I bought it. The painted portion was rusty, the chrome portion was bent and covered with flat black spray paint, the wiring grommet was gone, and it had quite a bit of rust inside. (After all, they're out in the nasty rain and stuff under the hood.) I dissected it and tweaked a couple things for a bench tryout. It spun, but not too well, and no noise at all came from it. But, as I said, it spun so I was happy with my purchase. After I tried it out, I left it in pieces and put it in a box for safekeeping, basically forgetting about it. A year or two later when I bought my GMC I had a renewed interest in it. Let's make that baby work!I tore it down and spent quite a bit of time straightening it and cleaning the paint off the chrome end of the horn with various chemicals until it shone again. To treat all the rust I used this stuff I got at Lowe's for about $15. Like most similar products, you just paint it on and it converts the dry, rusty area into a hard, shiny, black surface that's a perfect base. Here you can see what it looks like after I painted the stuff onto the rust inside the horn bell and let it dry.

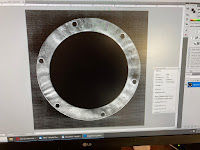

When I tore it apart, almost all the screws holding it together twisted off when I tried to unscrew them, and the paper gaskets on either side of the drum head were almost totally disintegrated. Well, there are no Hutchins oogah horn paper gaskets anywhere on planet Earth that I know of, so obviously I had to make them. No problem--we have a Cricut here at our place, and it makes awesome gaskets!